SURVIVAL THROUGH QUALITY

PRODUCT CENTER

-

Pulse dust collector

-

Mine dust collector

-

Boiler dust collector

-

Metallurgical dust collector

-

Carbon plant dust collector

-

Chemical dust collector

-

Rubber dust collector

-

Woodworking dust collector

-

Single machine dust collector

-

Static electricity Dust collector

-

Cyclone dust collector

-

Wet dust collector

-

Filter cartridge dust collector

-

Insert valve (gate valve)

-

Ventilation butterfly valve (cold air valve)

-

Spiral conveyor (auger)

-

Scraper conveyor

-

Dust humidifier

-

Bucket elevator

-

Ash discharge valve

-

Material Handling Equipment

-

Wet scrubber

-

Dust collector

-

Dust removal filter bag

-

Dust removal bag cage

-

Polishing platform

-

Waste gas treatment equipment

-

Electric control cabinet

-

Fan

-

Smoke welding machine

-

Liquid level switch

-

Dust removal filter element

-

Aeration cushion

-

Sweeper

-

Dust suppression device

-

Solenoid valve

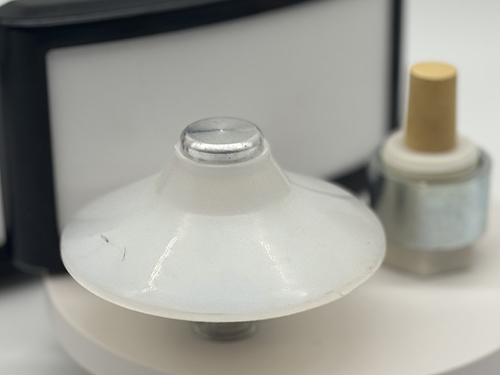

Aeration cushion

Aerated cushion layer filters are divided into upstream and downstream types. Downflow refers to the treatment method of filtering sewage downwards from the upper part of the filter. Due to the insufficient load, a large amount of intercepted SS is concentrated several tens of centimeters above the filter, so the head loss here accounts for the head loss of the entire filter. They are mostly prone to clogging, have low filtration rate, short operating cycle, and are currently rarely used.

Upflow refers to the treatment method of filtering sewage from the bottom of the filter upwards. A typical upstream BAF is called a BIOFOR filter. The bottom is an air water mixing chamber, and the top is a long handled filter head, filter plate, aeration pipe, cushion layer, and filter material. The density of the filter material used is greater than the density of water, which naturally accumulates. The thickness of the filter layer is generally 2-4m. Wastewater enters the air water mixing chamber from the bottom, passes through a long handle filter head, and then enters the filter material through a cushion layer. The biofilm on the outer side of the filter material and the activated sludge between the filter materials jointly remove BODS, CODcr, ammonia nitrogen, and SS.

After a certain period of operation, the head loss of the filter increases, and backwashing is required to release suspended solids intercepted by the filler and biofilm that has fallen off. During backwashing, the water inlet is stopped, and air and water enter the gas-water mixing chamber simultaneously. They enter the filter material through a long handle filter head, and the backwashing mixed liquid flows into the initial sedimentation tank for joint treatment with the raw water. When the pool is used for nitrification and phosphorus removal, compressed air is introduced into the aeration pipe. When the pool is used for denitrification, the water containing carbon source is fed into the aeration pipe while adjusting other operating conditions such as hydraulic load.