SURVIVAL THROUGH QUALITY

PRODUCT CENTER

-

Pulse dust collector

-

Mine dust collector

-

Boiler dust collector

-

Metallurgical dust collector

-

Carbon plant dust collector

-

Chemical dust collector

-

Rubber dust collector

-

Woodworking dust collector

-

Single machine dust collector

-

Static electricity Dust collector

-

Cyclone dust collector

-

Wet dust collector

-

Filter cartridge dust collector

-

Insert valve (gate valve)

-

Ventilation butterfly valve (cold air valve)

-

Spiral conveyor (auger)

-

Scraper conveyor

-

Dust humidifier

-

Bucket elevator

-

Ash discharge valve

-

Material Handling Equipment

-

Wet scrubber

-

Dust collector

-

Dust removal filter bag

-

Dust removal bag cage

-

Polishing platform

-

Waste gas treatment equipment

-

Electric control cabinet

-

Fan

-

Smoke welding machine

-

Liquid level switch

-

Dust removal filter element

-

Aeration cushion

-

Sweeper

-

Dust suppression device

-

Solenoid valve

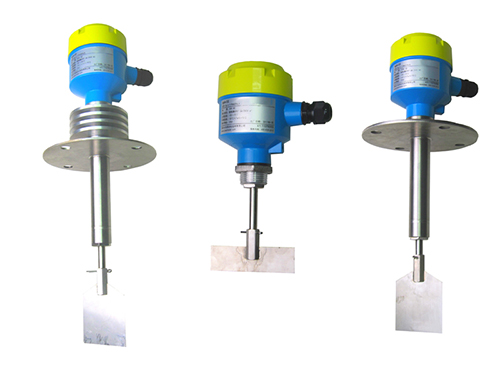

Material level meter

A level gauge refers to an instrument that detects real-time changes in the height of solid materials in a container.

Level gauge, also known as level transmitter, level controller, level gauge, level gauge, etc.

Measurement of the surface position of solid blocks or powders in a storage tank to understand the amount of material stored in the tank.

In thermal power plant, it is necessary to detect the position of coal and pulverized coal in raw coal hopper and pulverized coal bunker.

In the past, simple heavy hammer detection level meters were often used to detect material levels. Now, automatic heavy hammer detection level meters, nuclear radiation level meters, and ultrasonic level meters are used to detect material levels.

Particle position detection plays an important role in the production automation process of modern coal preparation plants. It is possible to estimate the volume or weight of the material stored in the container, maintain it at the required height, or alarm its upper and lower limit positions, continuously monitor or adjust the balance of incoming and outgoing materials in the container.

The commonly used instruments for automatic and continuous detection of coal bin level in coal preparation plants are electrode type, ultrasonic type, heavy hammer type, microwave type, and weighing type level meters.

Automatic heavy hammer detection level gauge

It consists of a servo motor, a steel wire rope suspended with a heavy hammer, a material level transmitter, and a display instrument with a microcomputer. After starting, the microcomputer sends a signal to lower the hammer, and the servo motor rotates to lower the heavy hammer. When the heavy hammer touches the material surface, the transmitter sends a signal to the microcomputer, causing the heavy hammer to stop falling and send a signal to raise the hammer. The motor reverses to raise the heavy hammer and sends a material level signal value to the display instrument.

After the heavy hammer rises to the top of the warehouse, the motor stops running. After a delay, repeat the above action. There are also devices on the display instrument that send alarms for the upper and lower limits of the material level.

Nuclear radiation type

The material level meter measurement system is equipped with a gamma ray radiation source on the lower side of the storage bin, and a gamma ray receiver on the upper side of the storage bin. As the height of the material surface changes, the intensity of the gamma rays passing through the material layer also varies. The receiver detects the intensity of the injected gamma rays and displays the height of the material level through a display instrument.

Ultrasonic level gauge

The top of the storage bin is equipped with an ultrasonic generator and receiver facing the material surface. The ultrasonic waves emitted by the generator are reflected upon reaching the material surface through the air layer, and a portion of the reflection is received by the receiver.

The height of the material level can be calculated by multiplying the time it takes for ultrasonic waves to be emitted and received by the speed of sound. Due to the influence of air temperature on the propagation speed of sound waves, it is necessary to measure the air temperature to correct the speed of sound.

Ultrasonic level meters are suitable for measuring the level of bulk materials with larger particle sizes.