SURVIVAL THROUGH QUALITY

PRODUCT CENTER

-

Pulse dust collector

-

Mine dust collector

-

Boiler dust collector

-

Metallurgical dust collector

-

Carbon plant dust collector

-

Chemical dust collector

-

Rubber dust collector

-

Woodworking dust collector

-

Single machine dust collector

-

Static electricity Dust collector

-

Cyclone dust collector

-

Wet dust collector

-

Filter cartridge dust collector

-

Insert valve (gate valve)

-

Ventilation butterfly valve (cold air valve)

-

Spiral conveyor (auger)

-

Scraper conveyor

-

Dust humidifier

-

Bucket elevator

-

Ash discharge valve

-

Material Handling Equipment

-

Wet scrubber

-

Dust collector

-

Dust removal filter bag

-

Dust removal bag cage

-

Polishing platform

-

Waste gas treatment equipment

-

Electric control cabinet

-

Fan

-

Smoke welding machine

-

Liquid level switch

-

Dust removal filter element

-

Aeration cushion

-

Sweeper

-

Dust suppression device

-

Solenoid valve

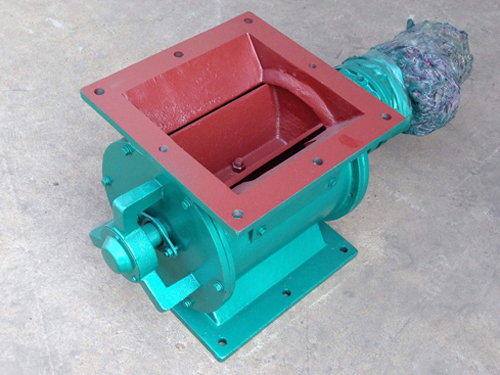

YJD-A Star shaped Discharger

The YJD-A star shaped unloader is the main equipment for dust removal equipment, ash discharge, air supply, and other equipment feeding, suitable for powdered and granular materials. Widely used in industrial sectors such as environmental protection, metallurgy, chemical industry, grain, and food.

When the star shaped unloader is working, dust falls by gravity and fills the star shaped blade spaces on the top and sides. The blade rotor is driven by an electric motor through a reducer shaft, and the impeller rotates to the lower part to remove dust by its own weight.

1、 When the material in the upper silo falls and fills the gap between the blades by its own weight, it is discharged from the lower part with the rotation of the blades. Therefore, the star shaped unloader can discharge the material quantitatively and continuously.

2、 The star shaped discharge device is commonly used in pneumatic output systems. For pressure output systems or negative pressure output systems, the star shaped discharge device can uniformly and continuously supply material to the conveying pipe. The gas and solid in the pneumatic output pipe are relatively stable, so that the pneumatic conveying can work normally. At the same time, it can also isolate the upper and lower air pressures of the discharge device and play a locking role. Therefore, the star shaped unloader is an important component commonly used in pneumatic conveying systems:

Before leaving the factory, the reducer of the star shaped unloader has been filled with lubricating oil No. 00 grease, and the ash discharge valve has been filled with lithium based grease. Within 6-10 months of use, the transmission and bearing components should be supplemented or replaced with grease. If the ambient temperature is high, humid, or there is too much dust in the air, the oil change time should be appropriately shortened. The star shaped discharge device is widely used as a common equipment in dust removal equipment. This type of machine, also known as electric ash discharge valve, electric air distributor, star shaped feeder, etc., is the main equipment for conveying, discharging, closing the air, and feeding other equipment during operation. It is suitable for passing through powdered and granular materials.

The YJD-A star shaped unloader is the main equipment for dust removal equipment, ash discharge, air supply, and other equipment feeding, suitable for powdered and granular materials. Widely used in industrial sectors such as environmental protection, metallurgy, chemical industry, grain, and food.

The characteristics of YJD-A star shaped unloader:

1. Compact structure, beautiful appearance, and convenient use.

2. Smooth operation and low noise.

3. Due to the distance between the bearings and gearbox from the housing, there is a significant impact on high temperature and lubrication.

4. The YJD-A star shaped unloader uses No. 00 reducer lubricating grease. Please check and add oil regularly.

5. Our factory can also design and manufacture (bracket coupling, belt chain drive) according to user requirements.

Precautions for using YJD-A star shaped unloader:

1. Before using the YJD-A star shaped unloader, check the quantity and type of lubricating oil in the reducer, replace it with new oil after running for one month, and replace it once a year thereafter;

2. Connect the YJD-A star shaped unloader to the air source interface and check if the interface is blocked by foreign objects, ensuring that the interface is clean;

3. Before using the YJD-A star shaped unloader, make sure that the rotation direction of the rotor is clockwise (when viewed from the extended shaft end of the reducer, it is consistent with the arrow on the sprocket cover);

4. Before using the YJD-A star shaped unloader, open the sprocket cover to check the tension of the chain, and regularly check it during operation; Apply appropriate lubricating grease to both the chain and sprocket simultaneously;

5. During the whole use process of YJD-A star discharger, adjust the pressure reducing valve to make the pressure at the seal greater than 0.05MPa of the material pressure in the valve body. The gas is oil-free, dry compressed air;

6. Throughout the use of the YJD-A star shaped unloader, the gas source at the sealing point always exists. Only when it is confirmed that the valve is shut down can the gas source be turned off.

Type | Volume per revolution | Speed-down motor model | Rew | Work temperature | Weight | Installation Dimension | |||||||||

| KW | r/min | ℃ | Kg | A | B | C | A1 | B1 | C1 | H | L | L1 | N-Φ | ||

| 2type | 2Vertical rise/rotation | Y801-4/0.55 | 24 | ≤80 | 55 | Φ240 | Φ200 | Φ150 | 240 | 200 | 150 | 240 | 530 | 585 | 8-Φ11 |

| 4type | 4Vertical rise/rotation | Y801-4/0.55 | 24 | ≤80 | 65 | Φ280 | Φ240 | Φ180 | 280 | 230 | 180 | 280 | 560 | 615 | 8-Φ13 |

| 6type | 6Vertical rise/rotation | Y801-4/0.55 | 24 | ≤80 | 75 | Φ300 | Φ260 | Φ200 | 290 | 250 | 200 | 300 | 585 | 635 | 8-Φ13 |

| 8type | 8Vertical rise/rotation | Y802-4/0.75 | 24 | ≤80 | 85 | Φ320 | Φ280 | Φ220 | 310 | 270 | 220 | 320 | 600 | 655 | 8-Φ13 |

| 10type | 10Vertical rise/rotation | Y90S-4/1.1 | 24 | ≤80 | 95 | Φ340 | Φ300 | Φ240 | 330 | 290 | 240 | 340 | 650 | 710 | 8-Φ15 |

| 12type | 12Vertical rise/rotation | Y90S-4/1.1 | 24 | ≤80 | 110 | Φ360 | Φ320 | Φ260 | 350 | 310 | 260 | 360 | 670 | 730 | 8-Φ15 |

| 14type | 14Vertical rise/rotation | Y90S-4/1.1 | 24 | ≤80 | 120 | Φ380 | Φ340 | Φ280 | 380 | 330 | 280 | 380 | 690 | 750 | 8-Φ18 |

| 16type | 16Vertical rise/rotation | Y90S-4/1.1 | 24 | ≤80 | 150 | Φ400 | Φ360 | Φ300 | 400 | 350 | 300 | 400 | 710 | 770 | 8-Φ18 |

| 18type | 18Vertical rise/rotation | Y90L-4/1.5 | 24 | ≤80 | 180 | Φ420 | Φ380 | Φ320 | 420 | 370 | 320 | 420 | 760 | 820 | 8-Φ18 |

| 20type | 20Vertical rise/rotation | Y90L-4/1.5 | 24 | ≤80 | 190 | Φ440 | Φ400 | Φ340 | 440 | 390 | 340 | 440 | 780 | 840 | 8-Φ18 |

| 26type | 26Vertical rise/rotation | Y100L-4/2.2 | 24 | ≤80 | 250 | Φ500 | Φ460 | Φ400 | 510 | 450 | 400 | 520 | 870 | 930 | 8-Φ18 |

| 30type | 30Vertical rise/rotation | Y100L-4/2.2 | 24 | ≤80 | 265 | Φ540 | Φ500 | Φ440 | 540 | 490 | 440 | 560 | 1100 | 1100 | 8-Φ18 |